Zvigadzirwa

Stainless Steel Hex Musoro Bolts

Tsananguro yechigadzirwa

| Chigadzirwa Zita | 304 Stainless Steel Hex Musoro Bolts |

| Zvinhu | Yakagadzirwa kubva pamakumi matatu neshanu isina simbi, idzi screws dzive nemakemikari akanaka emakemikari uye anogona kunge ari munyama. Ivo vanozivikanwawo seA2 Stainless Simbi. |

| Musoro Rudzi | Hex musoro. |

| Kureba | Inoyerwa kubva pasi pemusoro. |

| Thread mhando | Coarse tambo, tsvina yakanaka. Madhiri akashongedza ndiyo indasitiri mwero; Sarudza izvi zviyero kana iwe usingazive gomba kana tambo pane inch. Yakanaka uye yakawedzera-yakanaka-tambo dzakanyatso kusimbiswa kudzivirira kusunungura kubva mukuvharidzira; iyo yakanaka iyo tambo, iri nani kupokana. |

| Standard | Screws iyo inosangana neApp's b18.2.1 kana yaimbova din 933 zvirevo zvinoenderana neiyi mhedzisiro zviyero. |

Application

Simbi isina tsvina hex inowana maflts akawanda maindasitiri akasiyana-siyana nekuda kwekukanganisa kwavo, simba uye kusimba. Iyo Hexagonal musoro inobvumidza kusimbisa nyore nyore ne wrench kana socket. Heano mamwe mafaro anowanzoita esimbi simbi hex hex bolts:

Mashandisiro eMarine:

Simbi isina tsvina Hex inopesana neCorrosion, ichiita kuti vakwanise kushandiswa munzvimbo dzekuvakwa kwechikepe uye kugadziriswa.

Oiri negesi gasi:

Hex Bolts anoshandiswa mukuvakwa uye kuchengetedza kwemafuta bhigi, pombi, uye zvimwe zvinoshandiswa mumaindasitiri yeaini negesi.

Mishini yekurima:

Inoshandiswa mukugadzira kwemidziyo yekurima uye michina, senge matirakiti nemapango.

Renewable Enerper Projects:

HEX Bolts anoshandiswa mukuvakwa kwemhepo turbines, solar panel zvivakwa, uye zvimwe zvinoshamisa zvesimba masimba masimba.

Zvivakwa zvemvura zvekurapa:

Bolts Bolts anoshandirwa mukereke uye kuchengetedza kwezvirimwa zvemvura, anoverengera zvakachengetedzeka mumidziyo dzakasiyana siyana uye zvivakwa.

Chikafu uye chinwiwa kugadziriswa:

Simbi isimbi Hexagon Bolts yakakodzera chikafu uye chinomera indasitiri nekuda kwekurwisa kwavo kupesana, kushandiswa mukereke yekugadzirisa michina.

HVAC (Kupisa, Ventilation, uye Mhepo Yemhepo):

Inoshandiswa mukuiswa uye kugadzirisa kweHVAC system yekuchengetedza zvikamu uye zvivakwa.

Stainless Steel Hex Bolts Din 933

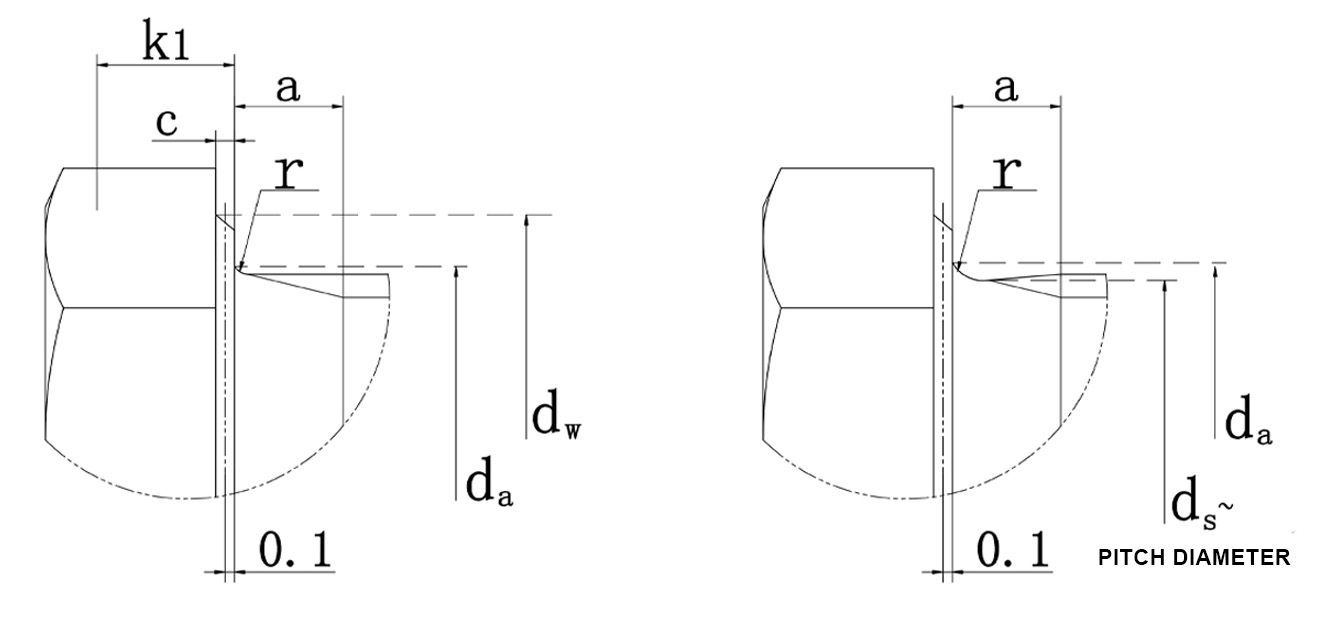

| Screw Thread | M1.6 | M2 | M2.5 | M3 | (M3.5) | M4 | M5 | M6 | (M7) | M8 | M10 | M12 | (M14) | M16 | ||||

| d | ||||||||||||||||||

| P | Pitch | 0.35 | 0.4 | 0.45 | 0.5 | 0.6 | 0.7 | 0.8 | 1 | 1 | 1.25 | 1.5 | 1.75 | 2 | 2 | |||

| a | Max | 1.05 | 1.2 | 1.35 | 1.5 | 1.8 | 2.1 | 2.4 | 3 | 3 | 3.75 | 4.5 | 5.25 | 6 | 6 | |||

| c | min | 0.1 | 0.1 | 0.1 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.2 | |||

| Max | 0.25 | 0.25 | 0.25 | 0.4 | 0.4 | 0.4 | 0.5 | 0.5 | 0.5 | 0.6 | 0.6 | 0.6 | 0.6 | 0.8 | ||||

| da | Max | 2 | 2.6 | 3.1 | 3.6 | 4.1 | 4.7 | 5.7 | 6.8 | 7.8 | 9.2 | 11.2 | 13.7 | 15.7 | 17.7 | |||

| dw | Giredhi a | min | 2.4 | 3.2 | 4.1 | 4.6 | 5.1 | 5.9 | 6.9 | 8.9 | 9.6 | 11.6 | 15.6 | 17.4 | 20.5 | 22.5 | ||

| Giredhi b | min | - | - | - | - | - | 5.7 | 6.7 | 8.7 | 9.4 | 11.4 | 15.4 | 17.2. | 20.1 | 22 | |||

| e | Giredhi a | min | 3.41 | 4.32 | 5.45 | 6.01 | 6.58 | 7.66 | 8.79 | 11.05 | 12.12 | 14.38 | 18.9 | 21.1 | 24.49 | 26.75 | ||

| Giredhi b | min | - | - | - | - | - | 7.5 | 8.63 | 10.89 | 11.94 | 14.2. | 18.72 | 20.88 | 23.91 | 26.17 | |||

| k | Saizi yezita | 1.1 | 1.4 | 1.7 | 2 | 2.4 | 2.8 | 3.5 | 4 | 4.8 | 5.3 | 6.4 | 7.5 | 8.8 | 10 | |||

| Giredhi a | min | 0.98 | 1.28 | 1.58 | 1.88 | 2.28 | 2.68 | 3.35 | 3.85 | 4.65 | 5.15 | 6.22 | 7.32 | 8.62 | 9.82 | |||

| Max | 1.22 | 1.52 | 1.82 | 2.12 | 2,52 | 2.92 | 3.65 | 4.15 | 4.95 | 5.45 | 6.56 | 7.68 | 8.98 | 10.18 | ||||

| Giredhi b | min | - | - | - | - | - | 2.6 | 3.26 | 3.76 | 4.56 | 5.06 | 6.11 | 7.21 | 8.51 | 9.71 | |||

| Max | - | - | - | - | - | 3 | 3.74 | 4.24 | 5.04 | 5.54 | 6.69 | 7.79 | 9.09 | 10.29 | ||||

| k1 | min | 0.7 | 0.9 | 1.1 | 1.3 | 1.6 | 1.9 | 2.28 | 2.63 | 3.19 | 3.54 | 4.28 | 5.05 | 5.96 | 6.8 | |||

| r | min | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.2 | 0.2 | 0.25 | 0.25 | 0.4 | 0.4 | 0.6 | 0.6 | 0.6 | |||

| s | max = zita rezita | 3.2 | 4 | 5 | 5.5 | 6 | 7 | 8 | 10 | 11 | 13 | 17 | 19 | 22 | 24 | |||

| Giredhi a | min | 3.02 | 3.82 | 4.82 | 5.32 | 5.82 | 6.78 | 7.78 | 9.78 | 10.73 | 12.73 | 16.73 | 18.67 | 21.67 | 23.67 | |||

| Giredhi b | min | - | - | - | - | - | 6.64 | 7.64 | 9.64 | 10.57 | 12.57 | 16.57 | 18.48 | 21.16 | 23.16 | |||

| Screw Thread | (M18) | M20 | (M22) | M20 | (M27) | M30 | (M33) | M30 | (M39) | M42 | (M45) | M48 | (M52) | ||||

| d | |||||||||||||||||

| P | Pitch | 2,5 | 2,5 | 2,5 | 3 | 3 | 3.5 | 3.5 | 4 | 4 | 4.5 | 4.5 | 5 | 5 | |||

| a | Max | 7.5 | 7.5 | 7.5 | 9 | 9 | 10.5 | 10.5 | 12 | 12 | 13.5 | 13.5 | 15 | 15 | |||

| c | min | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | |||

| Max | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 1 | 1 | 1 | 1 | 1 | ||||

| da | Max | 20.2 | 22.4 | 24.4 | 26.4 | 30.4 | 33.4 | 36.4 | 39.4 | 42.4 | 45.6 | 48.6 | 52.6 | 56.6 | |||

| dw | Giredhi a | min | 25.3 | 28.2 | 30 | 33.6 | - | - | - | - | - | - | - | - | - | ||

| Giredhi b | min | 24.8 | 27.7 | 29.5 | 33.2 | 38 | 42.7 | 46.5 | 51.1 | 55.9 | 59.9 | 64.7 | 69.4 | 74.2 | |||

| e | Giredhi a | min | 30.14 | 33.53 | 35.72 | 39.98 | - | - | - | - | - | - | - | - | - | ||

| Giredhi b | min | 29.56 | 32.95 | 35.03 | 39.55 | 45.2 | 50.85 | 55.37 | 60.79 | 66.44 | 71.3 | 76.95 | 82.6 | 88.25 | |||

| k | Saizi yezita | 11.5 | 12.5 | 14 | 15 | 17 | 18.7 | 21 | 22.5 | 25 | 26 | 28 | 30 | 33 | |||

| Giredhi a | min | 11.28 | 12.28 | 13.78 | 14.78 | - | - | - | - | - | - | - | - | - | |||

| Max | 11.72 | 12.72 | 14.22 | 15.22 | - | - | - | - | - | - | - | - | - | ||||

| Giredhi b | min | 11.15 | 12.15 | 13.65 | 14.65 | 16.65 | 18.28 | 20.58 | 22.08 | 24.58 | 25.58 | 27.58 | 29.58 | 32.5 | |||

| Max | 11.85 | 12.85 | 14.35 | 15.35 | 17.35 | 19.12 | 21.42 | 22.92 | 25.42 | 26.42 | 28.42 | 30.42 | 33.5 | ||||

| k1 | min | 7.8 | 8.5 | 9.6 | 10.3 | 11.7 | 12.8 | 14.4 | 15.5 | 17.2. | 17.9 | 19.3 | 20.9 | 22.8 | |||

| r | min | 0.6 | 0.8 | 0.8 | 0.8 | 1 | 1 | 1 | 1 | 1 | 1.2 | 1.2 | 1.6 | 1.6 | |||

| s | max = zita rezita | 27 | 30 | 32 | 36 | 41 | 46 | 50 | 55 | 60 | 65 | 70 | 75 | 80 | |||

| Giredhi a | min | 26.67 | 29.67 | 31.61 | 35.38 | - | - | - | - | - | - | - | - | - | |||

| Giredhi b | min | 26.15 | 29.16 | 31 | 35 | 40 | 45 | 49 | 53.8 | 58.8 | 63.1 | 68.1 | 73.1 | 78.1 | |||

Ansi / Asme b18.2.1

| Screw Thread | 1/4 | 5/16 | 3/8 | 7/16 | 1/2 | 5/8 | 3/4 | 7/8 | 1 | 1-1 / 8 | 1-1 / 4 | 1-3 / 8 | 1-1 / 2 | |

| d | ||||||||||||||

| PP | Unc | 20 | 18 | 16 | 14 | 13 | 11 | 10 | 9 | 8 | 7 | 7 | 6 | 6 |

| Unf | 28 | 24 | 24 | 20 | 20 | 18 | 16 | 14 | 12 | 12 | 12 | 12 | 12 | |

| 8-UN | - | - | - | - | - | - | - | - | - | 8 | 8 | 8 | 8 | |

| ds | Max | 0.26 | 0.324 | 0.388 | 0.452 | 0.515 | 0.642 | 0.768 | 0.895 | 1.022 | 1.149 | 1.277 | 1.404 | 1.531 |

| min | 0.237 | 0.298 | 0.36 | 0.421 | 0.482 | 0.605 | 0.729 | 0.852 | 0.976 | 1.098 | 1.223 | 1.345 | 1.47 | |

| s | Max | 0.438 | 0.5 | 0.562 | 0.625 | 0.75 | 0.938 | 1.125 | 1.312 | 1.5 | 1.688 | 1.875 | 2.062 | 2.25 |

| min | 0.425 | 0.484 | 0.544 | 0.603 | 0.725 | 0.906 | 1.088 | 1.269 | 1.45 | 1.631 | 1.812 | 1.994 | 2.175 | |

| e | Max | 0.505 | 0.577 | 0.65 | 0.722 | 0.866 | 1.083 | 1.299 | 1.516 | 1.732 | 1.949 | 2.165 | 2.382 | 2.598 |

| min | 0.484 | 0.552 | 0.62 | 0.687 | 0.826 | 1.033 | 1.24 | 1.447 | 1.653 | 1.859 | 2.066 | 2.273 | 2.48 | |

| k | Max | 0.188 | 0.235 | 0.268 | 0.316 | 0.364 | 0.444 | 0.524 | 0.604 | 0.7 | 0.78 | 0.876 | 0.94 | 1.036 |

| min | 0.15 | 0.195 | 0.226 | 0.272 | 0.302 | 0.378 | 0.455 | 0.531 | 0.591 | 0.658 | 0.749 | 0.81 | 0.902 | |

| r | Max | 0.03 | 0.03 | 0.03 | 0.03 | 0.03 | 0.06 | 0.06 | 0.06 | 0.09 | 0.09 | 0.09 | 0.09 | 0.09 |

| min | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.02 | 0.02 | 0.02 | 0.03 | 0.03 | 0.03 | 0.03 | 0.03 | |

| b | L≤6 | 0.75 | 0.875 | 1 | 1.125 | 1.25 | 1.5 | 1.75 | 2 | 2.25 | 2,5 | 2.75 | 3 | 3.25 |

| L> 6 | 1 | 1.125 | 1.25 | 1.375 | 1.5 | 1.75 | 2 | 2.25 | 2,5 | 2.75 | 3 | 3.25 | 3.5 | |

| Screw Thread | 1-5 / 8 | 1-3 / 4 | 1-7 / 8 | 2 | 2-1 / 4 | 2-1 / 2 | 2-3 / 4 | 3 | 3-1 / 4 | 3-1 / 2 | 3-3 / 4 | 4 | |

| d | |||||||||||||

| PP | Unc | - | 5 | - | 2004/1/2 | 2004/1/2 | 4 | 4 | 4 | 4 | 4 | 4 | 4 |

| Unf | - | - | - | - | - | - | - | - | - | - | - | - | |

| 8-UN | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | |

| ds | Max | 1.658 | 1.785 | 1.912 | 2.039 | 2.305 | 2,559 | 2.827 | 3.081 | 3.335 | 3.589 | 3.858 | 4.111 |

| min | 1.591 | 1.716 | 1.839 | 1.964 | 2.214 | 2.461 | 2.711 | 2.961 | 3.21 | 3.461 | 3.726 | 3.975 | |

| s | Max | 2.438 | 2.625 | 2.812 | 3 | 3.375 | 3.75 | 4.125 | 4.5 | 4.875 | 5.25 | 5.625 | 6 |

| min | 2.356 | 2.538 | 2.719 | 2.9 | 3.262 | 3.625 | 3.988 | 4.35 | 4.712 | 5.075 | 5.437 | 5.8 | |

| e | Max | 2.815 | 3.031 | 3.248 | 3.464 | 3.897 | 4.33 | 4.763 | 5.1996 | 5.629 | 6.062 | 6.495 | 6.928 |

| min | 2.616 | 2.893 | 3.099 | 3.306 | 3.719 | 4.133 | 4.546 | 4.959 | 5.372 | 5.786 | 6.198 | 6.612 | |

| k | Max | 1.116 | 1.196 | 1.276 | 1.388 | 1.548 | 1.708 | 1.869 | 2.06 | 2.251 | 2.38 | 2,572 | 2.764 |

| min | 0.978 | 1.054 | 1.13 | 1.175 | 1.327 | 1.479 | 1.632 | 1.815 | 1.936 | 2.057 | 2.241 | 2.424 | |

| r | Max | 0.09 | 0.12 | 0.12 | 0.12 | 0.19 | 0.19 | 0.19 | 0.19 | 0.19 | 0.19 | 0.19 | 0.19 |

| min | 0.03 | 0.04 | 0.04 | 0.04 | 0.06 | 0.06 | 0.06 | 0.06 | 0.06 | 0.06 | 0.06 | 0.06 | |

| b | L≤6 | 3.5 | 3.75 | 4 | 4.25 | 4.75 | 5.25 | 5.75 | 6.25 | 6.75 | 7.25 | 7.75 | 8.25 |

| L> 6 | 3.75 | 4 | 4.25 | 4.5 | 5 | 5.5 | 6 | 6.5 | 7 | 7.5 | 8 | 8.5 | |